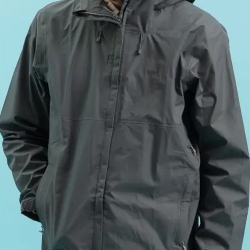

Winter clothing is vital to protect human beings from harsh weather. The Winter Jackets Manufacturers in USA follow a very important process to ensure durability, insulation, and comfort for high-quality performance. Quality assurance is thus not about industry standards but about betterment over expectations by delivering jackets that stand the test of time.

Selecting High Performance Materials

The movement towards the high-quality jacket really starts with the selection of premium materials. Fabric is the thing that can change everything regarding the jacket's performance in the extreme of weather conditions. Manufacturers carefully select insulating layers, water-resistant coating, and breathable linings to obtain the right balance of warmth and comfort. Thus it goes for sportswear, like volleyball uniforms from leading Volleyball Uniform Manufacturers in Australia, are designed from lightweight to robust fabrics allowing an athlete that moves and gets cool. Thus, winter apparel has to provide the person warmth without compromising mobility, just as volleyball players want clothes to support their performance.

Fabric Tests for Endurance

The first step towards production is conducting thorough tests to check all materials regarding the standard of durability under which they lie. The fabric has to stand numerous tests under stress in order to determine how effective it is against tearing, moisture, and temperature extremes. The level of water resistance is also a major aspect of this; fine winter jackets must repel snow and rain without losing their heat insulation. These test laboratories have controlled conditions wherein to simulate the incoming resource conditions in order to measure and evaluate insulation, breathability, and overall durability. Thus, the jackets pass on to the next stage of production phase after they get approved by these tests, and the ones that fail this stage are kept for re-examination to ensure that only the best would eventually make it to the final product.

Precision in Design and Construction

The design phase is where functionality marries craftsmanship. Innovative techniques are employed to enrich the warmth while keeping the jacket light and flexible. Advanced stitching methods, such as seam sealing, help prevent heat loss and increase water resistance. High-performance athletic gear, such as rash guards from prominent Rash Guards Manufacturers in UK, also relies on precise stitching and ergonomic design to provide comfort and durability. Likewise, winter apparel is built with reinforcement along all points of stress to ensure durability even under strenuous outdoor conditions.

Quality Control Inspections

Quality control before a jacket reaches the consumer involves a number of different checkpoints. It is the place where the manufacturers do thorough inspections of detecting flaws in fabric or stitching or in insulation. These jackets are also tested for fitting, which determines how well it fits, and flexibility, with all range of motion, including extension, available without restriction. Thereafter, the manufacturers perform various wear-and-tear simulations to see how the jackets function after repeated uses.

Performance Testing in Real Conditions

Testing in-house isn't enough even after laboratory testing. Extreme weather conditions are subjected to jacket use to test insulation levels and resistance to water. With this, you will be assured that the jacket is to cut down on sub-zero temperatures, strong winds, and eventually snow from floating. This is the use of all such testing methods for every-day essential items like promotional bags from DRH Sports, one of the renowned Promotional Bags Manufacturers in USA, undergo rigorous, drainage-in household use while retaining their shape and quality. These build-up conditions in the laboratory may call forth to mini-test-stretch weaknesses before making ones designed.

Continuous Improvement Through Customer Feedback

The quality check does not end here. The jacket is manufactured and sold. Besides, the manufacturer never stops but keeps on collecting feedback from the users about their experience regarding how the product is standing in its day-to-day use. Thus, professional engineers can provide letters of well-studied observations to general toward casual users. This is considered invaluable in improving collections in the coming years. Other consumer reactions are those of complaint regarding fit, problems in insulation, and issues with durability. Quality-alliance uses these findings of consumer reactions in further improving designs. Hence, all new collections promise to be better than their last.

Beyond Production: A Commitment to Quality

Quality assurance in winter gear is hardly an end to a process but rather is a never-ending acquisition and aggressive learning about the cutting edge of technology, real life, and customer feedback. No matter how short the material fabric or how well-developed the final inspection process, each has been engineered to ensure jackets are good to go-wholly equipped with warmth and fit. Manufacturers that believe that such rigorous quality checks will take a stand on their standing offer in the industry where performance means all.